We use high speed and latest model 8 colours Rotogravure Printing Machine. Inspired by Italian technology and having German Control Panels. This machine has auto splice systems at both ends, auto registration sytem and auto print defect detection system.

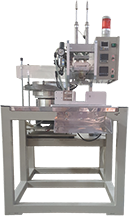

Three sides sealed, Stand up & Zipper Pouching Machine.

(Stand up Pouches with or without Ziplock / Three side Pouches / Centre Sealed Pouches with or without side Gusset / Inline Customized Punches / Notches etc.

High Speed Solvent Based and solvent less combination Lamination & Coating Machine. This machine also has feature of registered reverse cold seal aplication system.

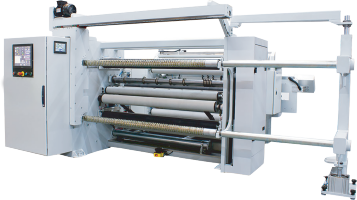

High Speed (600 meters per minute) Slitting Machines with Laser Guided Core Positioning and Edge Guide for Web Control. Having a diferent range of core inner and outer diameters capacity. Minimum sliting width as low as 25 mm, specially for wrap around lables for juice, dairy and water industries.

Air filter- regulator with auto drain device adjusts the air pressure. Good for pre-open zip stand up pouches with multi layers of polyester and sealant with or without aluminum foil. Good for pre-made side gusset coffee pouches. Capable to fix one way degassing valves with filter or without filter for better aroma, oxygen and moisture control for your products.

We have Italian origin central thermal oil heating system in our plant that distributes controlled and even heat for our daily operational needs for all machines, specially printing and lamination machines enabling quick drying, better quality and higher speed output.

We have American origin central chiling system in our plant that distributes controlled and even chilled water for our daily operational needs for all machines, enabling greater efficiency, better quality and higher speed output.

We have European origin central air compressor system in our plant that distributes controlled and even air pressure for our daily operational needs for all machines, enabling greater efficiency, better quality and higher speed output.